Grinders have been around for a very long time. Over the years many different types of grinders and grinding machines have developed. Do you know how many there are? Many are named after their form factor, design, or use case.

Keep in mind that each kind of grinder may look a little different from one to another, even if they’re the same type. Ranging from small handheld models to large industrial sizes, today we’ll look at the main different types of grinders you can use to cut and grind materials.

1. Angle Grinder

Angle grinders, also known as right angle grinders, side grinders, or disc grinders, are the most popular and common type of grinder. With a wide array of uses, these feature a wheel at a right angle to the handle shaft of the tool. This handheld power tool is often used in fabrication and construction work. Their versatility includes the ability to use them with many kinds of attachments and cutters.

2. Bench Grinder

Bench grinders are stationary machines typically attached and bolted down to a workbench or table. These feature two rotating abrasive wheels of different grain sizes for grinding down and shaping tools that need to be made or repaired. Wire brushes or buffing wheels can be interchanged with the grinding wheels to clean or polish workpieces.

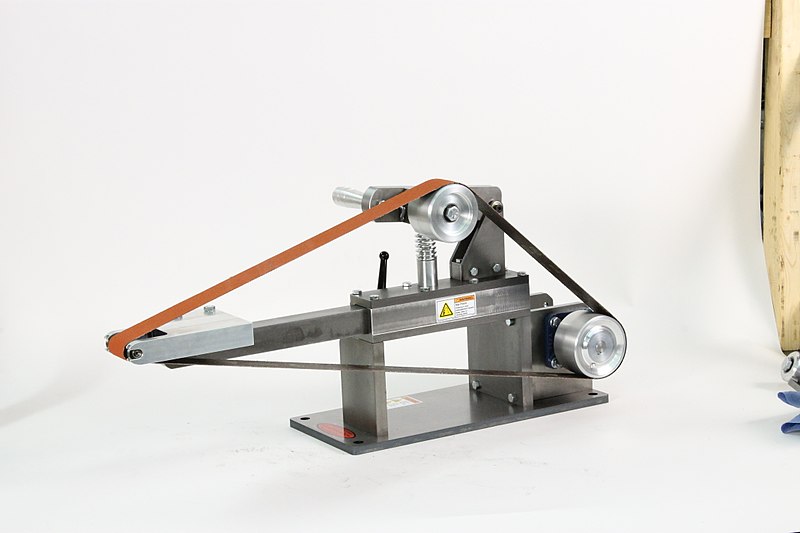

3. Belt Grinder

Belt grinders are primarily used for processing metals with coated abrasions. This could be for finishing surfaces, sharpening blades, deburring, or stock removal. Similar to belt sanders, these tools feature an abrasive coated belt that produces a finished surface when materials are run over it.

4. Wet Grinder

Abrasive cutting wet grinders are used to polish and grind stone and tiles. The fluid helps to lubricate and cool the grinder while the cutting wheel is in motion. The use of water also helps to reduce the risk of cracking or damaging the cutting tool or workpiece.

Numerous angle grinders, tile saws, and others used for woodworking and sharpening blades utilize water. Most hand-held models feature an abrasive disc to achieve a smooth finish. The following wet grinder works for polishing stone.

5. Die Grinder

Die grinders are small handheld highspeed rotary tools for shaping and polishing that feature a small diameter grinding bit. These tools can be used for grinding, sanding, honing, polishing, or machining material. Die grinders are available in both straight and right-angle heads. Many are powered by compressed air or by a small electric motor. Various attachments also allow for die grinders to be used for fabrication, engraving, contouring, and woodworking.

6. Floor Grinder

For larger commercial or residential work with lots of square footage, floor grinders are the best option. These abrasive tools work to wear down concrete surfaces, wood, or to clean tile and grout. Similar in size to a vacuum machine, floor grinders utilize horizontal rotating discs that remove surface material.

Conclusion

All the different types of grinders serve a purpose and solution for a particular situation. These machine tools work to grind down material using an abrasive wheel for the cutting tool in many shapes and sizes. With all the grinder attachments you have to choose from, you’re sure to specialize down the tool to your specific needs.